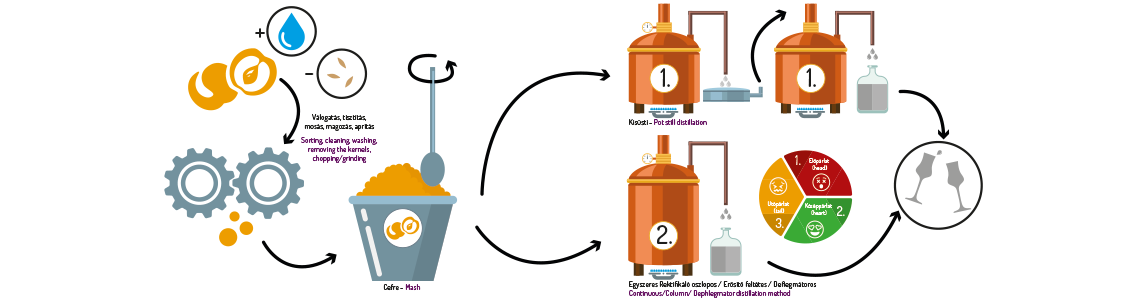

During the production of pálinka we produce a so called mash from the fruit and then this will be correctly distilled.

During the mashing the fruit will be sorted, cleaned, washed, the kernels will be removed, the fruit will be chopped according to its type, thereafter it’s important, that the fermentation should start at the right condition and proceed as planned. Due to the biological processes the mash starts to ferment, hence the sugar content of the fruit is converted to alcohol. Yet this alcohol content is fairly low, around 1-8% abv (alcohol by volume) in total.

THE DISTILLATION OF THE MASH HAS TWO IMPORTANT OBJECTIVES:

- increasing the alcohol content

- separating the volatile compounds (the mash has many volatile compounds, the less favourable ones have to be separated).

THE DISTILLATION / REFINING, DISTILLATE FRACTIONS:

- The head: beside the alcoholic character it reminds someone of solvent, „Spiritus menthae cum sale”, diluent, nail polish remover on the nose, it contains readily volatile substances.

- The heart or mid cut: this is the true pálinka, which shows the respectful fruit type, aroma and flavour, the alcohol content is around 60-86% abv (alcohol by volume), this is the fraction, meant for consumption.

- The tail: it is characterized as heavy, unpleasant, sour odour, due to the longer chain carbon molecules of alcohol (such as butanol, propanol, etc.), this gives the pálinka the itchy, scratchy flavour, if it is not separated.

THE PRODUCTION OF THE PÁLINKA CAN BE DONE BY TWO DIFFERENT DISTILLATION SYSTEMS:

1. One is called Kisüsti (kis means small and üsti means a traditional Hungarian pot, which is a maximal size of 1000-litre pot), also called as traditional double distillation method, this is the older process.

2. The other method goes in through a one course, single or better known as continuous system, yet several names reflect singularity (Rectification column, Column, Dephlegmator), that is more modern and energy-efficient.

1. DURING THE KISÜSTI (POT STILL DISTILLATION) PROCESS THE DISTILLATION TAKES PLACE IN TWO STEPS:

- During the first step with distillation 15-28% a.b.v. liquid is created, which contains all the volatile compounds, since there is no separation of fractions. This distillation is called raw spirit.

- In the second step the raw spirit is refined through re-distillation, whereby the alcohol content increases and with this the spirit fractions are also separated. The multiple distillations are energy-demanding processes (heating up and cooling down twice) as well as time consuming, hence modern technologies gain ground in the choice of the producers.

2. CONTINUOUS/COLUMN/ DEPHLEGMATOR DISTILLATION METHOD

With the continuous distillation the separation of the volatile compounds is made during the distillation, together with the alcohol content enrichment and the separation of the spirit fractions. The distilling system is used on the method of the rectification, which on the other hand is based on the principle of continuous distillation.

With both system it is true, that as the distillation process commences, the alcohol content is continuously decreasing in the mash and the quality of the volatile compounds is changing as well, according to their volatility. In order to obtain just the true characters of the fruit it is important to pay attention at the separation. The head, which comes at the beginning of the distillation ends, when the fine fruit aromas appear in the distillation, from here we call it heart. It is important to separate the heart and the tail from each other as well, at the right time (even at 65-68% abv) and finish the distillation. The alcohol received from the heart can be adjusted by adding soft water, dilute the product to the desired value.

THE FUNCTION OF COPPER – THE STRUCTURAL MATERIAL OF THE DISTILLATION EQUIPMENTS

The distillation equipments have been made for centuries from (red) copper, not only because they look nice, but their good conductivity of metal, resistance against the acidic environmental of the mash and moreover their positive impact in terms of aromas during distillation were recognized. Its disadvantage however is the amortisation (it ecomes thinner), hence from time to time, it needs to be changed. Due to the technological improvement, the use of stainless steel materials became widespread amongst the industrial equipments, but the red copper has not yet been replaced by all the components.

The equipment can or must be made out of stainless steel, where there is a liquid phase, the corrosion is bigger, hence until the level of the mash in the pot, as well as in the cooling system of the distillation. At the steam phase – at the dome pot and the helmet or at column distillation at the plates/trays – it is useful to have a copper surface, since it promotes favourable transformation in the composition of aromatic precursors and binds the sulphur compounds as well.

Source

Panyik Gáborné dr., assistant professor – “A pálinkakészítés technológiája II., egyetemi jegyzet, Pálinkamester szakmérnök és szaktanácsadó szakirányú továbbképzési szak, Budapest Corvinus Egyetem Élelmiszertudományi Kar, Budapest 2013.,” Published : Budapest Corvinus University